Chain link fence DIY Installation tips

Building a Chain Link Fence

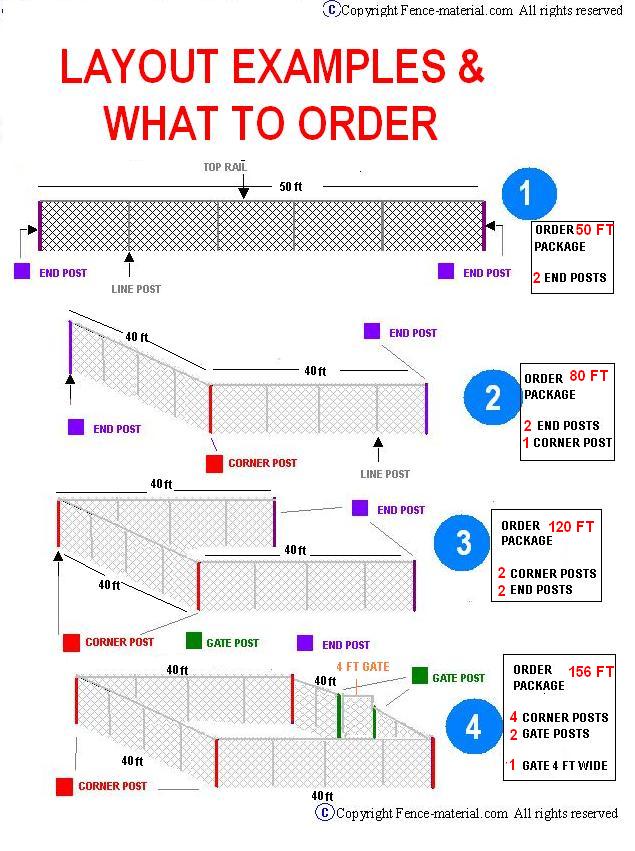

Chain link fences are durable and can provide excellent security. Because these fences don't block views, they are a good choice for keeping an eye on pets and small children. Our Complete Fence packages are listed with all the line posts with hardware, top rail, chain link mesh and ties. End posts, corner posts and gate posts are listed with hardware on package pages. Easy to Order "Fail Safe" Complete Packages in minutes, without worrying about individual hardware parts and pieces, its all automatic!. All you need to know is the height you need and the total footage. Enter in the cart total footage of package, End posts, Corner posts and Gates & Gate Posts. Our computer will calculate the total for you with the shipping cost.

Some people are intimidated by the number of components in a chain link fencing and although tall fences are best installed by a fence contractor, low chain link fences (48 inches or less) are actually simple to install. The biggest challenge may be tracking down a fence puller, the tool that stretches the chain link mesh between the posts. A fence puller consists of a winch (known as a come-along), a chain and a fence-pulling rod. You can use a come-a-long with a Fence Pull Chain and hooks to do the same thing.

Building the Fence

The first step in building a fence is planning the layout and then marking the fence location with stakes and string. Once you've done that, mark post locations along the string with bright-colored chalk. If you're installing the fence on a property line or if the fence must meet certain setback requirements, you'll need to establish the exact location of the line to avoid disputes with neighbors or to make sure the fence meets local ordinances.

Once you've located your property lines, mark the corners with surveyor's stakes or other markers. If you're building a fence within the property, establishing the locations of end posts and corner posts is usually done by measuring out from one or more existing reference points on the property, such as the house, the driveway, an existing fence or other landmarks. The information here explains how to locate posts for a straight fence built on flat ground with corners meeting at 90 degrees. It is likely your situation is not so ideal, but with these instructions and a little common sense, you can lay out posts for just about any fence design.

Project Basics:

Project: Moderate

Estimated Project Time: Several days

Start Tips:

Before you begin, contact your local planning council or building department to see what building codes, zoning laws and city ordinances affect the size, design and location of the intended fence.

Safety Tips:

Wear safety goggles when using power tools, such as a power auger.

Recommendation: Do-It-Yourself

Tools and Materials:

Chain link fence components

Fence puller (can be rented)

Measuring tape

1x2 wood stakes

String

Bright-colored chalk

Mason's twine

Nails

Hammer

Plumb bob

Spirit level

Long measuring stick

Heavy paper

Posthole digger or hand or power auger (can be rented)

Concrete

Shovel

Mason's hoe

Wheelbarrow

Scrap pieces of lumber

Lineman's pliers

Adjustable wrench

Safety goggles

Instructions

1) Mark the End Posts: Drive a 1x2 stake firmly into the ground, marking each end of the fence line. Drive a small nail into the top of each stake marking what will be the center of the fence posts. Stakes typically project 4 to 6 inches above ground; however, taller stakes may be required for the string to clear low obstructions along the fence line.

Digging the postholes will obliterate all your layout marks. Erect batter boards to make it easy to re-establish them. To build batter boards, drive two stakes about a foot apart, a few feet beyond each corner stake. Connect them with a crosspiece. Stretch mason's twine from crosspiece to crosspiece, positioning it so that it crosses the nail on the corner stakes.

2) Establish a 90-Degree Corner

So that each corner of the fence will form an exact 90-degree angle, lay them out using the 3-4-5 triangulation method.

Begin with the side you have laid out, which has the corners A and B in the drawing. Put a batter board about 12 inches beyond the approximate location of the third corner and another one about 12 inches beyond the opposite corner – corner B in the drawing. String a line from crosspiece to crosspiece so that it crosses the nail in the corner stake at point B. From the same corner stake, measure out 3 (or 6) feet along one string and 4 (or 8) feet along the other, and mark these measurements on the strings.

Have a helper slide the string along the far batter board until the diagonal distance between the marks equals 5 (or 10) feet. Mark the string location on the batter board. Mark the location of the terminal post on the string, hang a plumb bob or use a level to transfer this point to the ground, and drive a stake at this point (C).

3) Establish Additional Corners

To enclose three sides of the property, run a second string out from a batter board at point A, attach it to another batter board, and repeat the above procedure. To form a complete enclosure (fenced on all four sides), drive two batter boards slightly beyond each of the corner locations, adjust the strings until they intersect at 90 degrees at all four corners, then drive stakes where strings intersect.

4) Locate Line Posts Between Corners

Once you've established the fence line with stakes and string, measure the total length of each side from corner to corner. Then, measure and mark the location of the center of each line post along the string, spacing them no farther than 96 inches apart or as specified in the manufacturer's instructions and local building codes. Also establish the placement of the posts for the gate, if any.

5) Transfer Post Locations to the Ground

Use a plumb bob to transfer the marks from the string down to the ground and mark each post location on the ground using a nail stuck through a piece of paper or with a stake . Once all of the marks are in place, remove the string.

6) Dig Holes for Posts

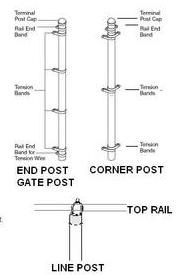

Using a posthole digger or a hand or power auger (can be rented), dig the postholes. Terminal (end, corner and gate) posts typically have a larger diameter than line (intermediate) posts. Postholes for terminal posts are typically 8 inches in diameter, and 18 to 30 inches deep. Holes for line posts are 6 inches in diameter and 18 to 24 inches deep, depending on the fence height and soil conditions.

In colder climates, set the posts below the frost line. Check local codes.

7) Set the Posts

All posts should be set in concrete. Use a fairly stiff mix, and frequently check the posts for plumb with a level. It's necessary to prop the posts with short lengths of lumber until the concrete sets. Set the terminal posts first. Once the terminal posts are in, attach a leveled string between them marking the height of the line posts. (Line posts are usually about four inches lower than terminal posts because the rails cross over them. Check your manufacturer's specifications.) Set the line posts to this height.

8) Add Top Rails

In one or two days, after the concrete has completely set, attach hardware to the terminal posts and to the top of the line posts. Slide onto each terminal post the tension bands (three or four, depending on fence height); a brace band to anchor the top rail; and a terminal post cap. If a corner post, it will need two brace bands.

Then gently tap the eye tops onto the line posts using a hammer and a block of wood.

Bolt the rail ends onto the brace bands on the terminal posts, and then install the top rails, slipping them through the eye-top connectors on the line posts and into the rail ends. Often, one end of each rail is reduced in diameter so that it can be connected snugly (nested) into the rail preceding it. In other cases, a top-rail sleeve may be required to connect rail ends. Rail-to-rail connections do not have to occur exactly above a post, although the installation will be stronger if they do.

9) Stretch the Chain Link

With a helper, unroll several feet of chain link mesh, and weave a tension bar into the end of the mesh. Attach the bar to the tension bands on the terminal post using the carriage bolts provided. Next, unroll the mesh to the other end of the fence, pull the mesh tight by hand, and weave a fence-pulling rod into the mesh about 36 inches in front of the end post. The pulling rod has holes through which you attach a chain with S-hooks in the ends. Hook one end of a come-along to the chain and the other end to the terminal post. Then crank the come-along to tighten the mesh.

As you work, test for tautness by pinching the mesh shut. The fence is taut enough when the openings close no more than about 1/2 inch. Weave a tension bar into the mesh even with the terminal post. Using lineman's pliers, cut the top and bottom links just beyond the tension bar. Undo the wire between the cuts to separate the mesh into two parts. Attach the tension bar to the tension bands using carriage bolts.

On short runs of fence with lightweight chain link, a come-along may not be needed. Simply have a helper stretch the mesh by hand as you fasten it to the posts.

10) Fasten Chain Link to the Rails

Attach the chain link mesh to the top rails and line posts using short pieces of galvanized wire or special tie wires, available from the supplier. Hook one end of the tie to the mesh, curl the tie over the post or rail, then hook the other end on the mesh. Space ties 24 inches apart on the rails and 12 inches apart on each line post.

On some designs, a heavy gauge wire is woven through the chain link mesh at the bottom of the fence. It is attached to the terminal posts to provide additional stability and to keep the chain link from bowing. Attach the wire to one terminal post by forming a loop around the post and cinching it with a cable clamp to cinch the wire. Weave the wire through the links about 4 inches above the bottom edge of the mesh, stretch it tight, and attach to the opposite terminal post.

11) Install the Gate

Gates usually come with hinges and latch attached. For an extra cost, you can have the gate set up with chain link mesh. If you choose to do it yourself, weave a tension bar in one end of the chain link mesh and attach it to the gate frame using tension bands. Stretch the mesh hand tight, weave a second bar even with the gate frame, cut the mesh just beyond the tension bar, and attach with tension bands. Attach the top and bottom of the mesh to the gate frame using tie wires.

Next, determine which side of the gate will be hinged, install the post and gate hinges and the fork latch, and hang the gate on the pins. Test the gate and adjust the hinges if necessary. You also may have to adjust the fork latch so that it is at a comfortable height; 36 inches is common.